The Greatest Guide To Spandrel Insulation

Table of ContentsThe 10-Minute Rule for Spandrel InsulationSpandrel Panel Definition Fundamentals ExplainedHow Storefront Panels can Save You Time, Stress, and Money.

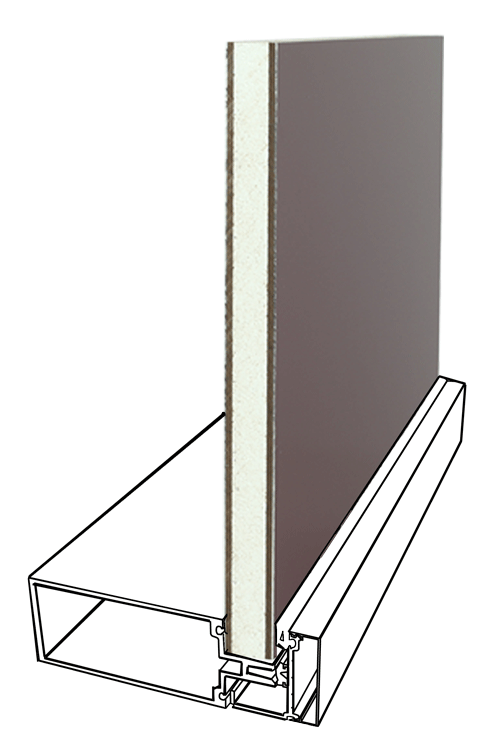

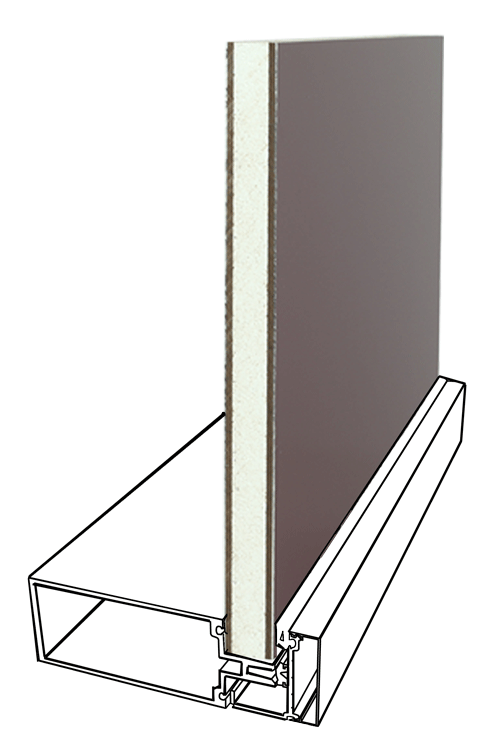

Real butt-glazing has no mullion or other back-up member behind the joint and relies exclusively on a sealant, usually silicone, in between the glass systems to provide a perfect barrier seal. AAMA's Curtain Wall Style Guide offers assistance on window choice for condensation resistance. Establish the needed Condensation Resistance Element (CRF) based on anticipated interior humidity and regional climate information and choose a drape wall with an appropriate CRF.The CRF does not provide information about cold spots that could result in regional condensation. Projects for which condensation control is a critical concern, such as high interior humidity buildings, require project-specific limited aspect analysis thermal modeling using software such as THERM. Careful analysis and modeling of interior conditions is required to accurately approximate the interior temperature level of the air at the within surfaces of the glass and frame - spandrel panel window.

g., an insulated boundary extrusion or metal panning). Consider frame geometry for thermally conductive aluminum frame materials. Minimize the proportion of framing exposed to the outdoors. Describe AAMA 1503 for descriptions of test method, parameters and equipment for determining U elements and CRF's for window items. Refer to NFRC 100 for U Aspect and NFRC 500 for condensation resistance.

The Greatest Guide To Spandrel Panel

Sometimes, there are issues associating with having excessive unrestrained daylight, sometimes described as glare - storefront panels. The obstacle is to pursue the highest visible light transmittance (VT) and the most affordable solar heat gain coefficient (SHGC) while not preventing the glass from being too reflective when seen from both the exterior and the interior, while managing glare.

2 program with Environmental Conditions set at NFRC 100 requirements. NFRC 200 is utilized to identify the VT and SHGC worths while the solar optical homes are identified utilizing NFRC 300. spandrel panel. Normally, for products more commonly available on the marketplace, the aforementioned values are readily available from glass manufacturers/fabricators. Aluminum: Class I anodic coatings (AAMA 611, supersedes AAMA 606, 607 and 608) and high performance factory used fluoropolymer thermoset coatings (AAMA 2605) have excellent resistance to ecological deterioration.

There isa wide variety of systems on the marketplace from producers that supply varying levels of reliability. Unitized systems range in efficiency browse this site capability from industry requirement to high efficiency walls. It is hence suggested that jobs defining unitized curtain wall systems integrate a group member who has a breadth of experience in designing and dealing with unitized systems.

Systems can be assembled in a factory while the structural frame of the building is being built. Where stick systems require multiple actions to put up and seal the wall, unitized walls show up on the website totally put together enabling the floorings to be closed in more quickly. Unitized systems also need less space on site for design thus offering a benefit for city websites with area restrictions.

Spandrel Panel Fundamentals Explained

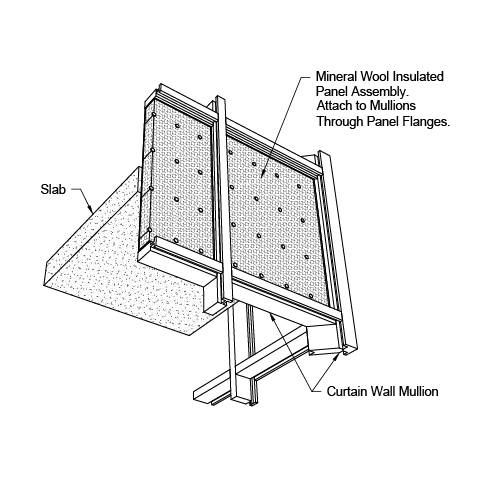

The interlocking vertical mullions will usually have two interlocking legs. One leg will be in the plane simply behind the glazing pocket and the other at the interior face of the mullions. The interlocking leg in the airplane of the glazing pocket will be sealed by gaskets and is the primary line of defense versus water and air infiltration.

These upstanding legs have gaskets that seal versus the walls of the bottom horizontal. Some designs provide one upstanding leg more that supplies one line of defense versus air and water infiltration. More robust systems will supply 2 upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is set up at the top of the two surrounding units as they are put up on the structure is usually required.

The stack joint is the horizontal joint where systems from adjacent floorings satisfy. Putting the stack joint at the sill of the vision glass (generally 30" above the flooring) will lessen the dimension of the vertical mullions. This positioning uses the back span of the mullion above the anchoring point at the slab to combat the deflection of the mullion listed below the slab.